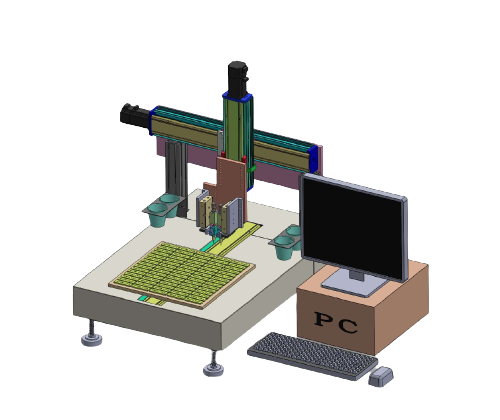

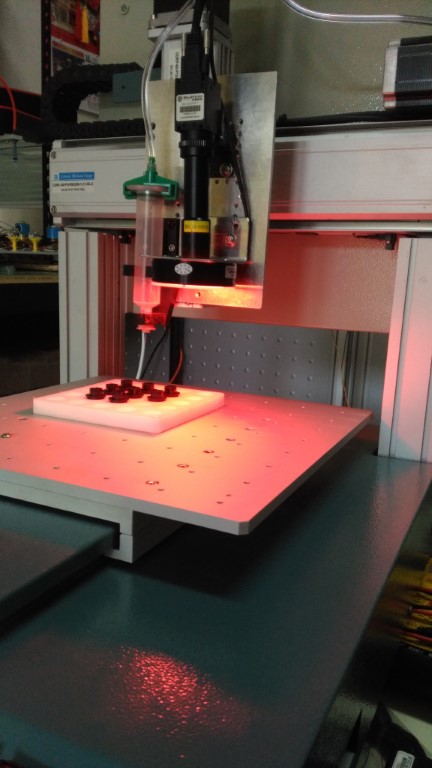

Desktop double glue gun dispensing machine (Visual Automatic Alignment)

CL010-B

Desktop double glue gun dispensing machine (Visual Automatic Alignment)

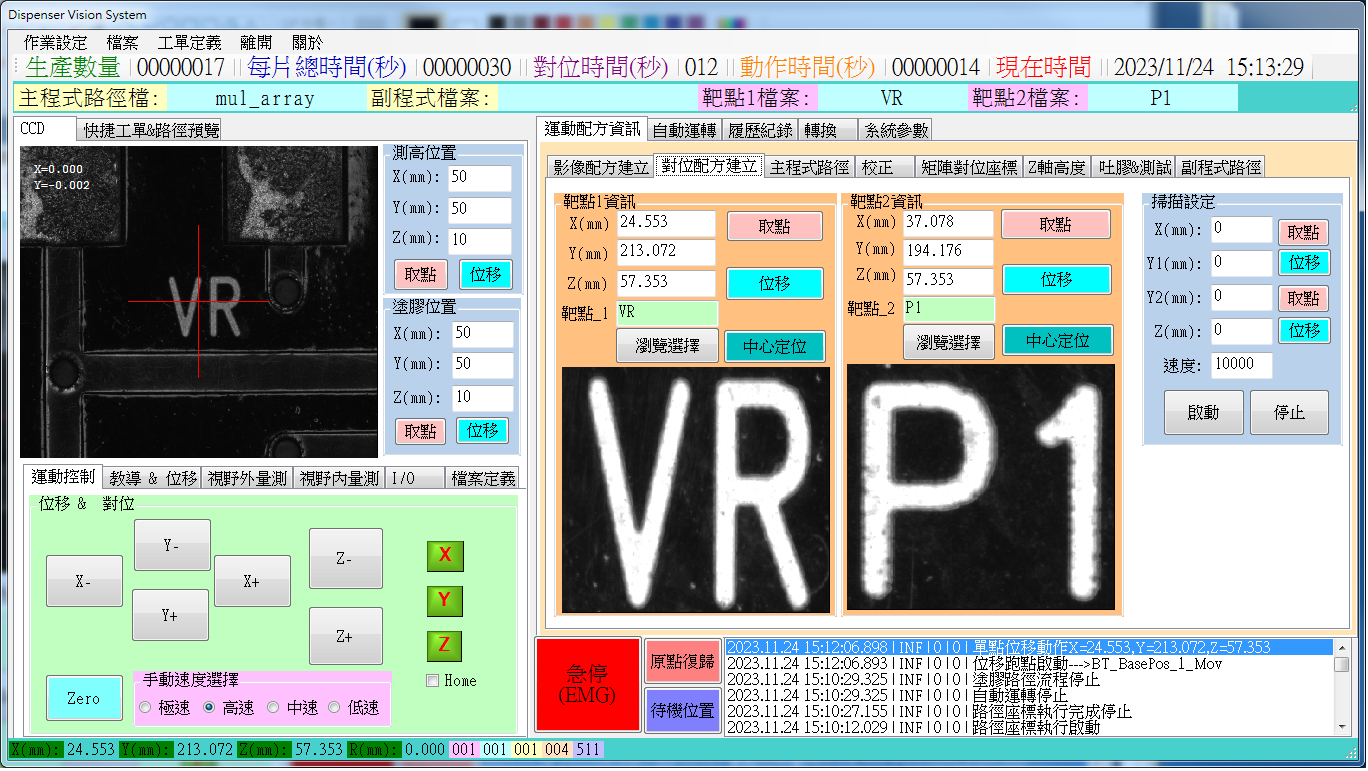

- Automatic visual alignment system

- Matrix arrangement or tray-in-turn-out fixture production mode

- CCD path automatic correction system

- Single-point/multi-point/any-point height measurement compensation object height confirmation difference

- Dual glue guns provide switching

- Automatic glue dispensing and glue gun cleaning on standby

- Quickly switch production recipes

- Quickly notify managers of real-time production information

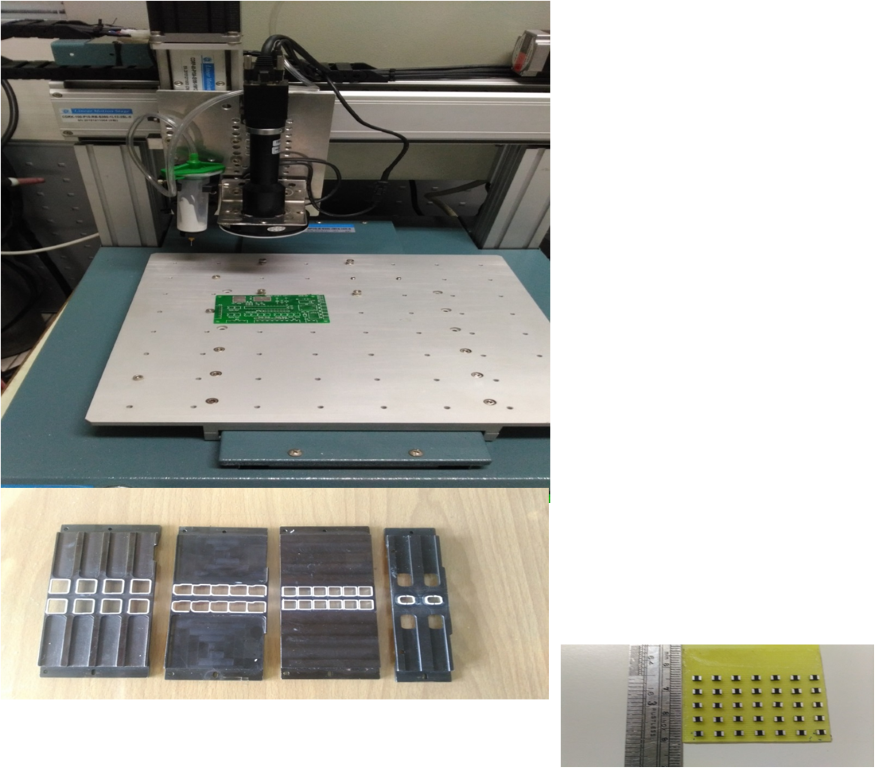

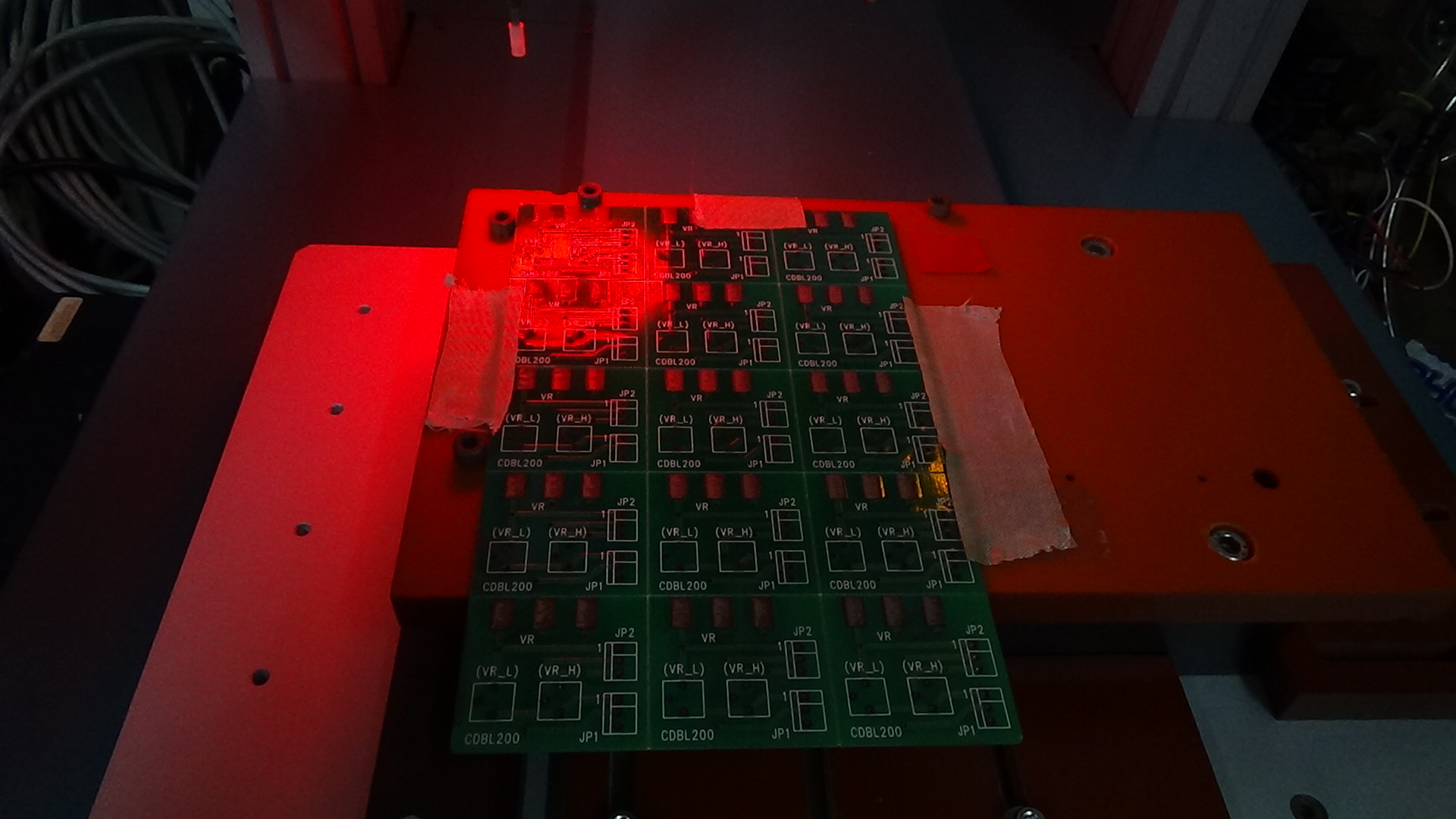

Regional matrix sample dispensing finished product

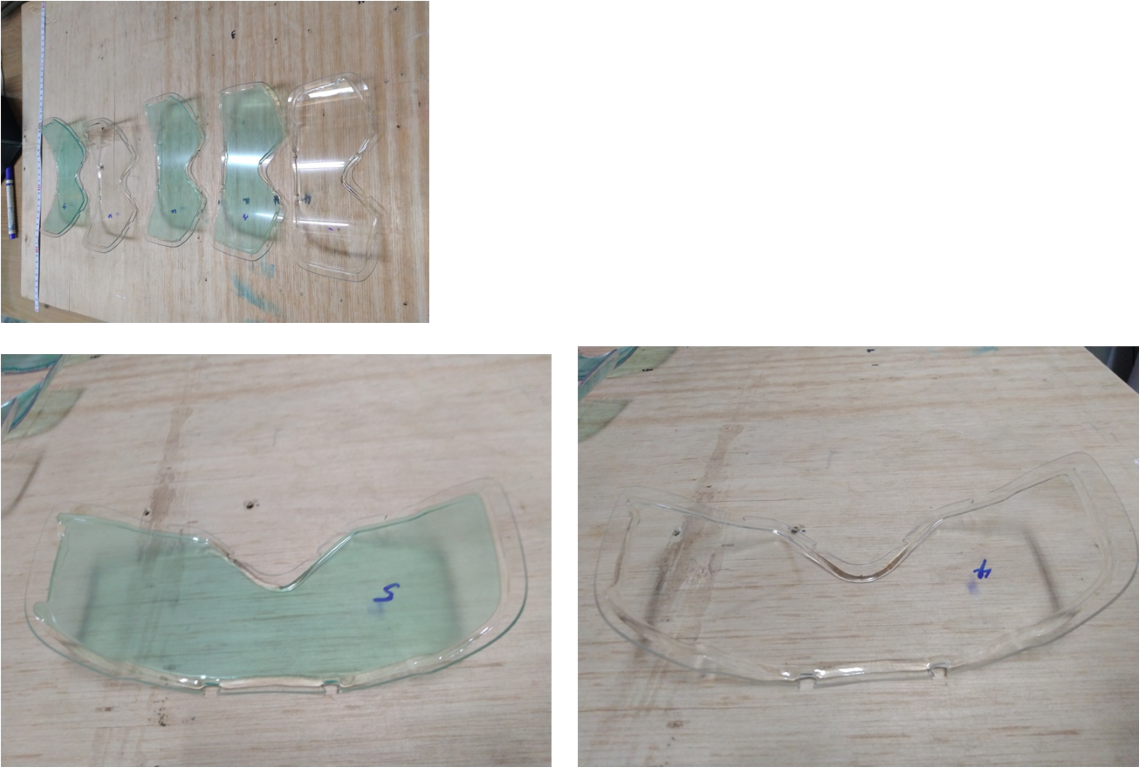

3D Glasses Glue Sample

Automotive lens dispensing

Material

Applicable material environment, metal surface, plastic surface, electronic products, glass surface bonding, optical lenses, chip bonding

Gluing

Applicable products are used in industries that require gluing.

Jig unstable

Applicable to unstable environments where product fixtures are placed.

Features

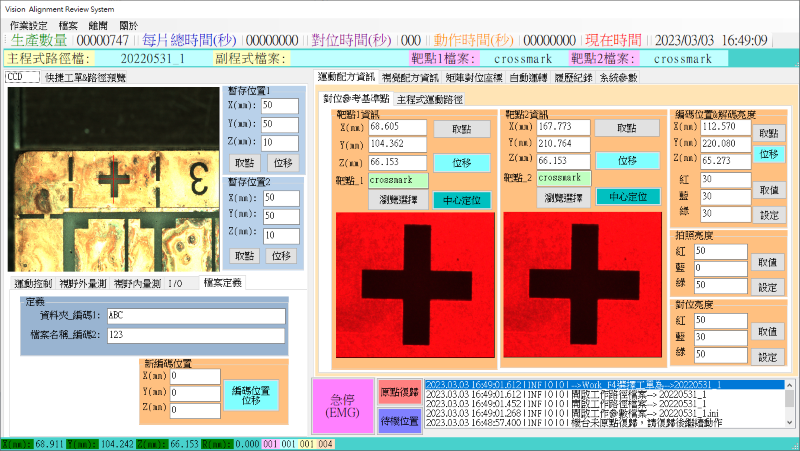

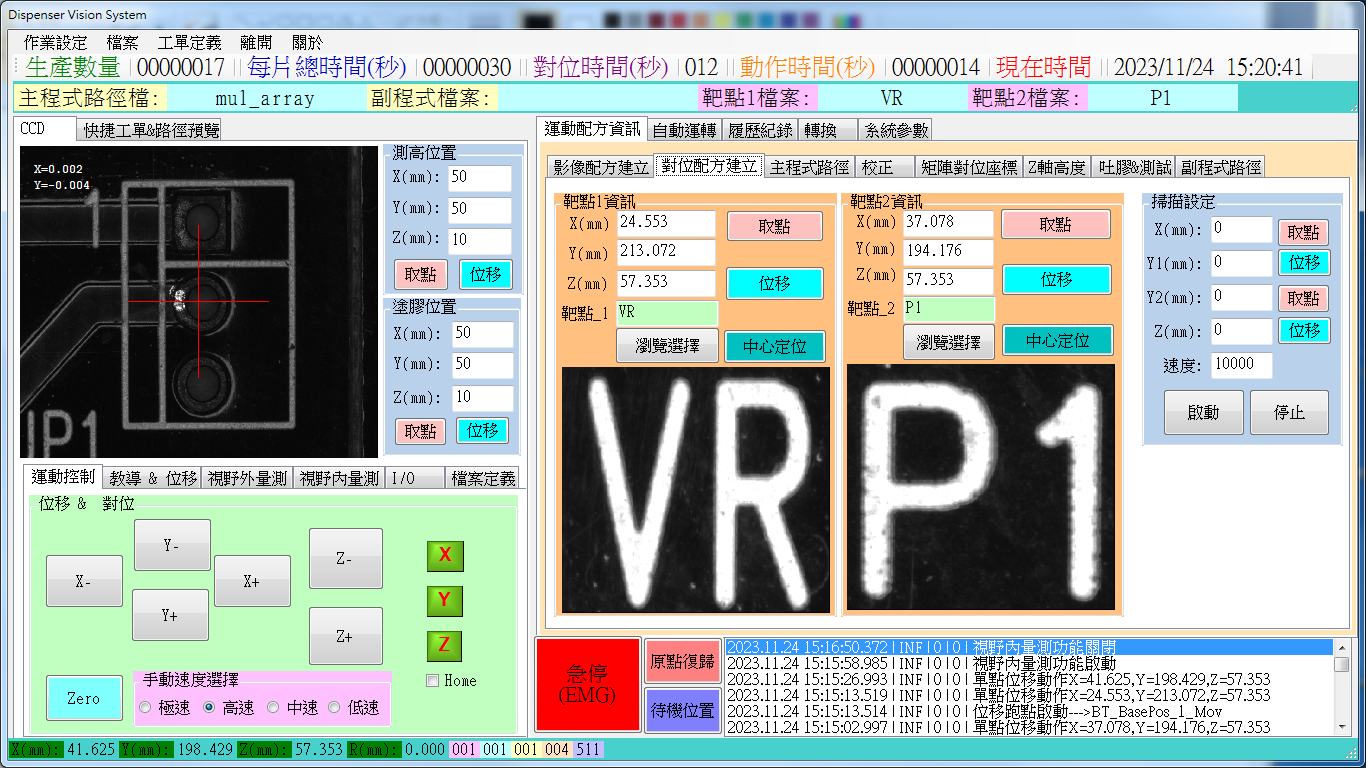

Automatic visual alignment system

The position within the field of view can not fixed, you can get it as long as you can see it.

Automatic visual alignment system

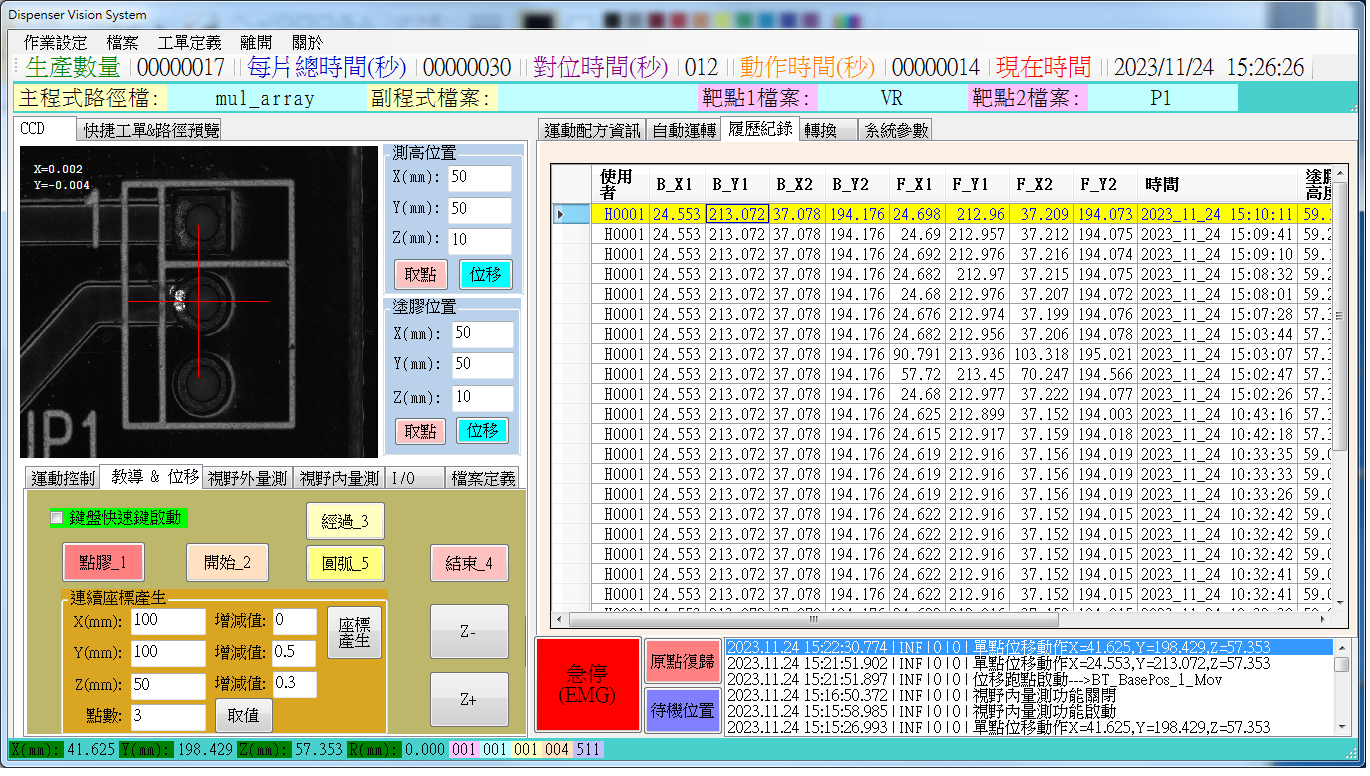

Matrix arrangement or tray-in-turn-out fixture production mode

Matrix arrangement or tray-in-turn-out fixture production mode

You only need to create a standard path template to calculate the matrix coordinates, greatly increasing the efficiency of product production.

CCD path automatic correction system

The product does not need to be placed at the same position and angle. All processing paths will be automatically re-corrected within the field of view.

CCD path automatic correction system

Single-point/multi-point/any-point height measurement compensation object height confirmation difference

Single-point/multi-point/any-point height measurement compensation object height confirmation difference

It can automatically correct the Z-axis point glue height to avoid damage to the glue gun needle.

Dual glue guns provide switching

Different glue types can be provided for easy switching at any time

Dual glue guns provide switching

Automatic glue dispensing and glue gun cleaning on standby

Automatic glue dispensing and glue gun cleaning on standby

Avoiding frequent needle changes or reducing glue gun hole plug problems can reduce consumable costs.

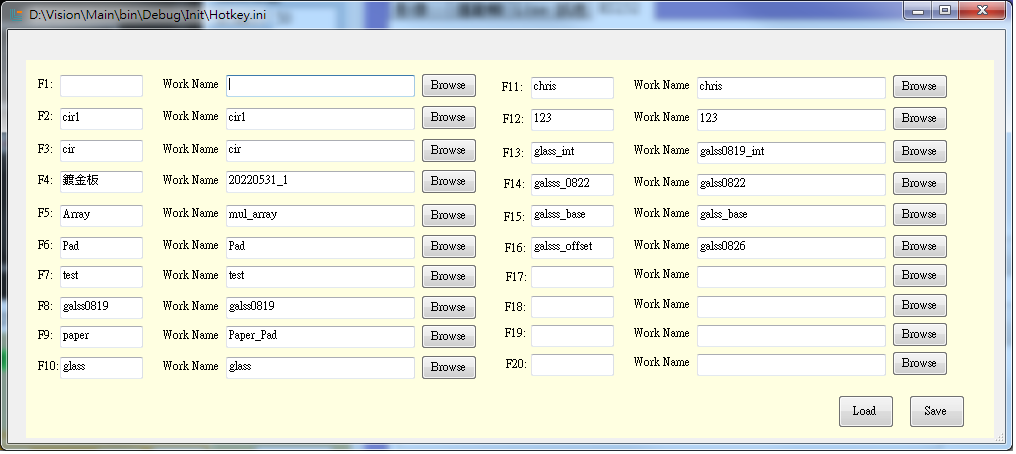

Quickly switch production recipes

Product formulas that have been produced can be activated directly and quickly.

Quickly switch production recipes

Quickly switch production recipes

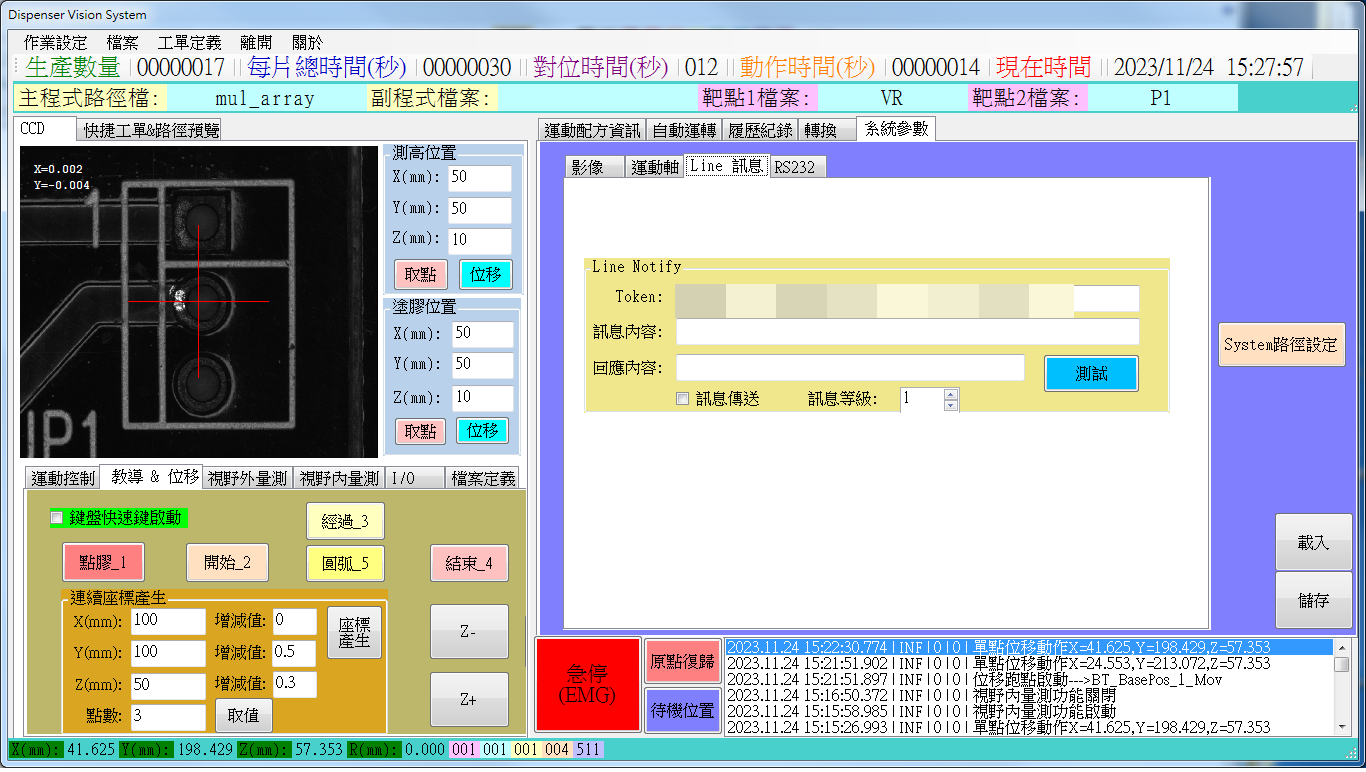

Quickly notify managers of real-time production information

Quickly notify managers of real-time production information

After the product is produced, notifications can be sent online, allowing managers to grasp the production status at one hand.

| Item | Value |

|---|---|

| Movement axis travel | X:600mm、Y:600mm、Z:100mm |

| Machine equipment size | 700mm(length)X700mm(depth)X500mm(height) |

| Available Job scope | X:400mm、Y:400mm |

| Platform load | 20kg |

| Maximum operating speed | 500mm/sec |

| Repeatability accuracy | ±0.01mm |

Authority management

- Personnel login permission control

- Distance measurement outside field of view

Measurement

Jog Control

- JOG displacement (speed switchable)

- Enter displacement at any position

- Absolute displacement

- Relative displacement

- Two-point reciprocating displacement (absolute displacement mode)

- Three-axis displacement process program (XYZ)

- Running points at each single point position

- Return to origin

- Two-axis linear interpolation (X, Y)

- Three-axis linear interpolation (X, Y, Z)

- Two-axis arc interpolation (X, Y)

- Point-to-point empty running alignment mode and production mode connection

- Manual operation interface for each axis

- Unit quantity conversion

- Axis card parameter adjustment, change field input mechanism and storage

- Axis card IO status display and control

- Single point mode and matrix process running point mode

- Forcefully specify the execution point location

- Automatic cleaning and dispensing

- Double glue gun switching goes online quickly

- Glue gun soaking

- Point empty running mode and production mode

- Production quantity counting and zeroing

- Return to origin

- Two-axis linear interpolation (X, Y)

- Three-axis linear interpolation (X, Y, Z)

Automatic operation

Job recipe adjustment

- Dot glue parameter adjustment

- Dispensing glue parameter delay and mode height switching provide settings

- Relative position correction of glue gun points (dual glue guns)

- Carving point file creation (XYZ)

- Quick engraving point array and template copy and file creation

- Quick and intuitive work order opening and preview

- Unlimited path storage

- Path preview

- Automatic offset compensation of visual alignment path

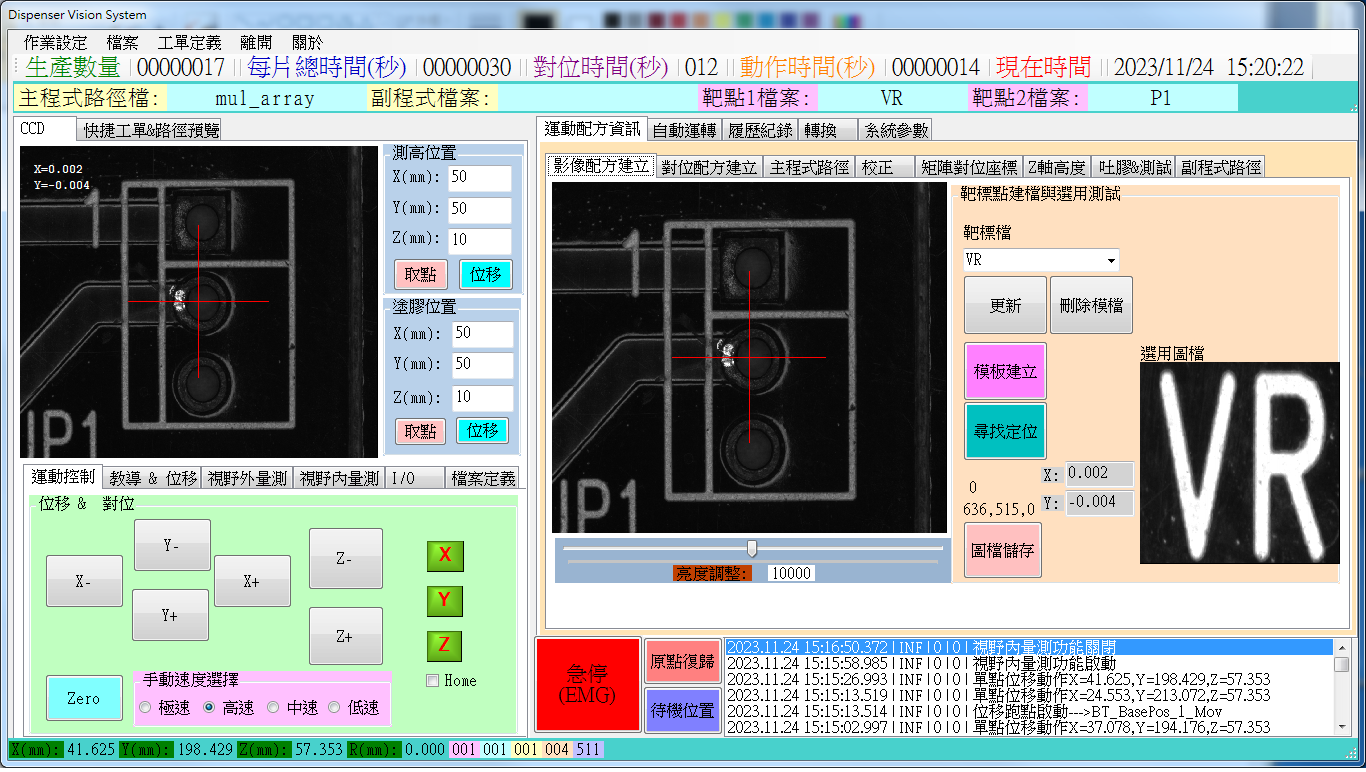

- CCD intuitive teaching

- Support different point positioning and shooting calculation path compensation

- Target automatic search and positioning

- Quickly click on the center of the screen to position

- Image decision center analysis and error compensation

- CCD alignment system

- Compare template files and recipe links

- Alignment information, work order link and template display

- Picture archive

- Light source brightness adjustment

Image positioning

Quickly establish the gluing position within the field of view

Wherever the camera can see, the coordinates can be built there

Quickly establish the gluing position within the field of view

Probe height measurement

Probe height measurement

The height can be dynamically confirmed to avoid needle damage.

Alignment data record

Can confirm whether the operator is working according to standard procedures

Alignment data record

Automatic search for objects in circles

Automatic search for objects in circles

Can automatically search for nearby alignment targets

Multiple template dot glue

Support core and cavity placed on the same disk

Multiple template dot glue

If the equipment specifications are different from your needs contact us for more information