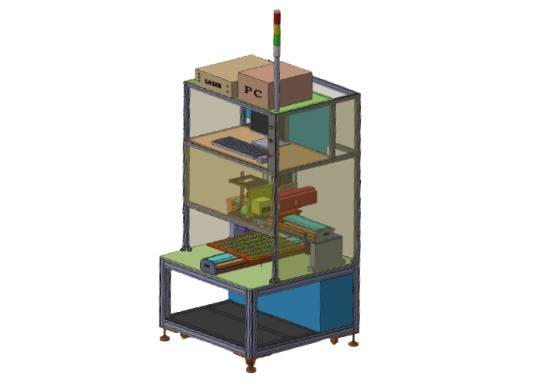

Floor-standing three-axis laser engraving machine (Visual Automatic Alignment)

CL011-C

Floor-standing three-axis laser engraving machine (Visual Automatic Alignment)

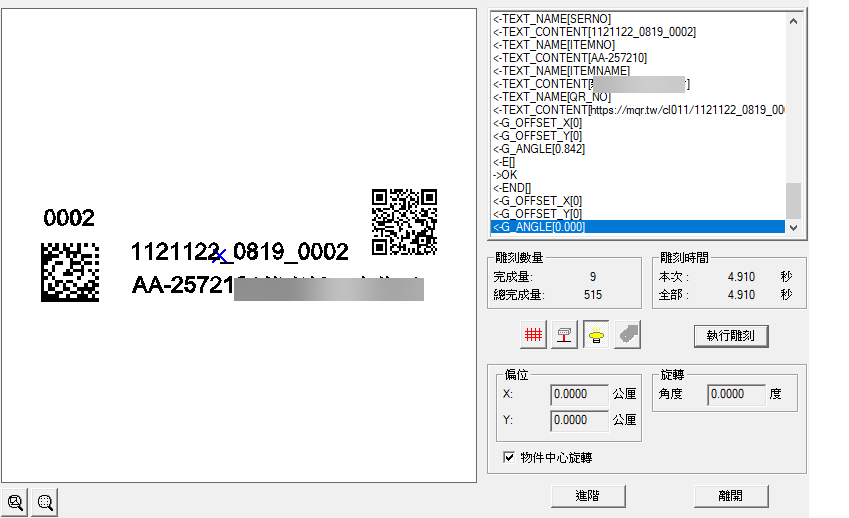

- Engraving information and laser software links

- Engraving content information can be dynamically changed

- Object loop automatic search

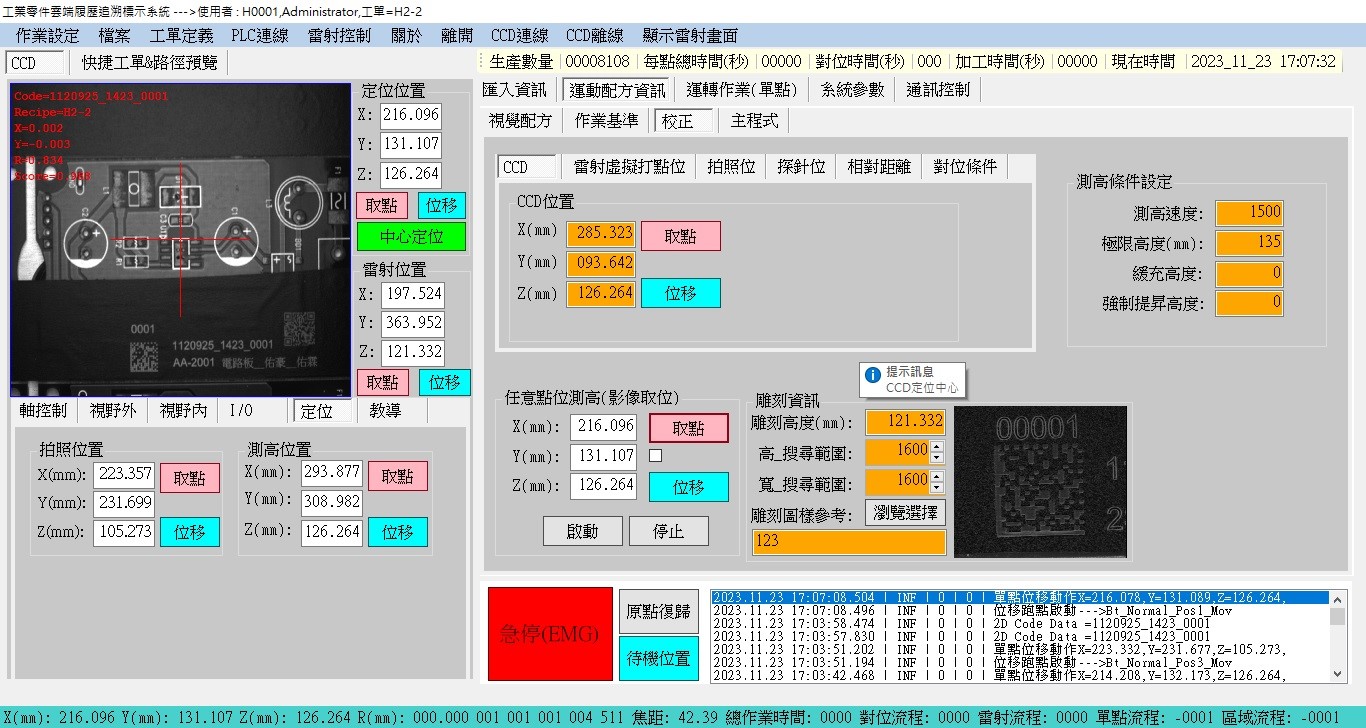

- Automatic probe height measurement

Material

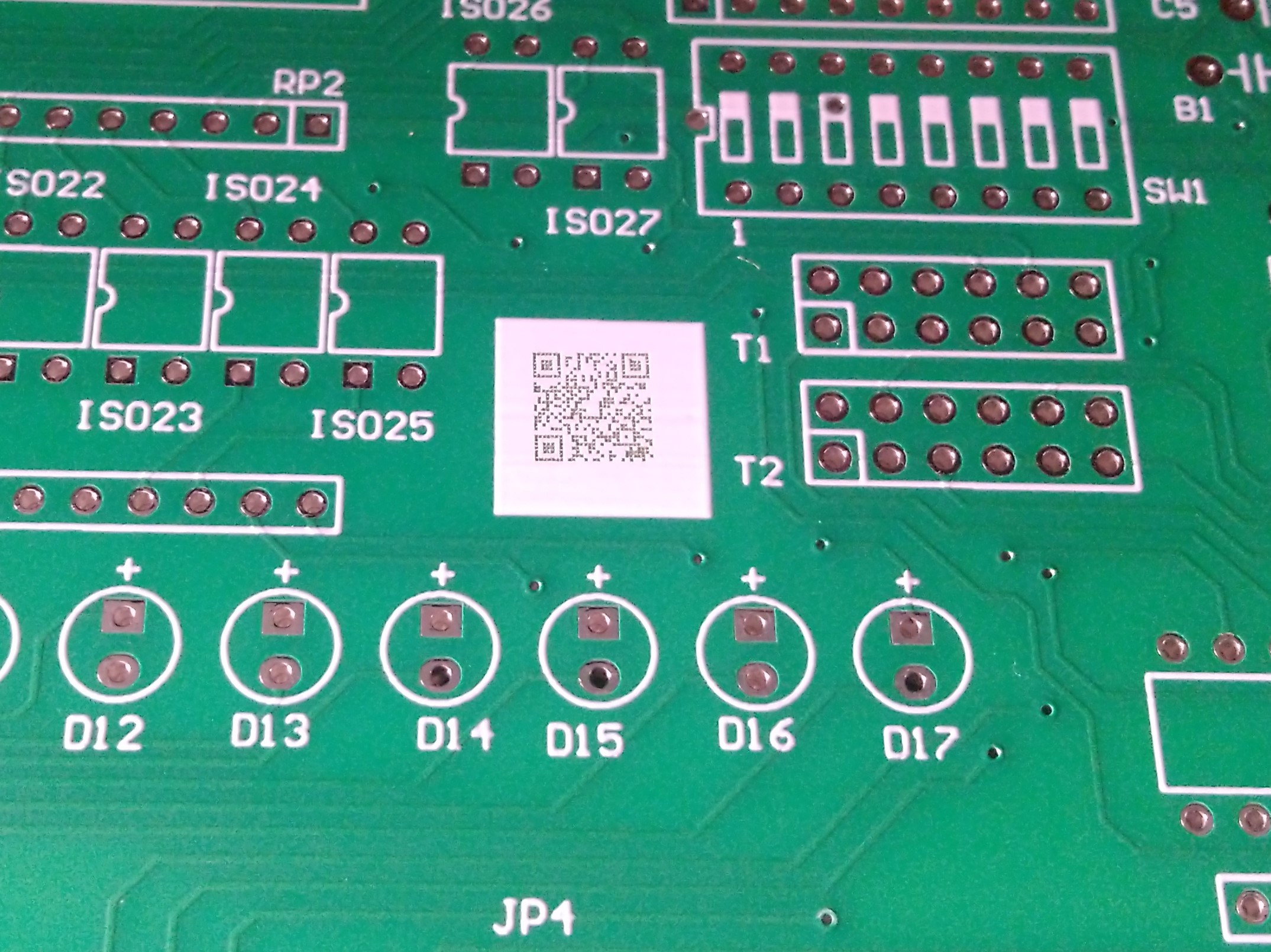

Metal surface, plastic surface, fiberglass surface

Factory

Applicable to factory environment, warehouse material labeling, and sales product specification labeling.

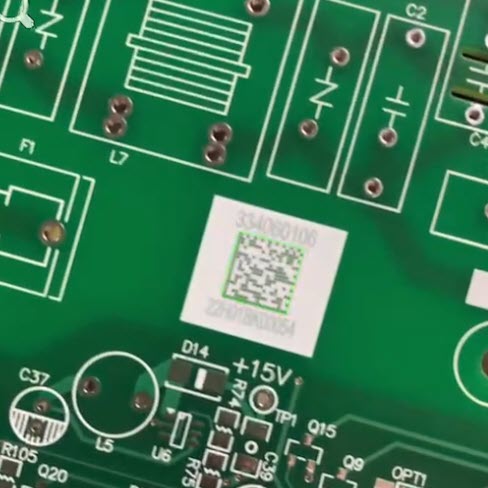

Unique label

Suitable for traceability product identification and unique coding identification.

Features

Engraving information and laser software links

Engraving content information can be dynamically changed

Object loop automatic search

Automatic probe height measurement (optional)

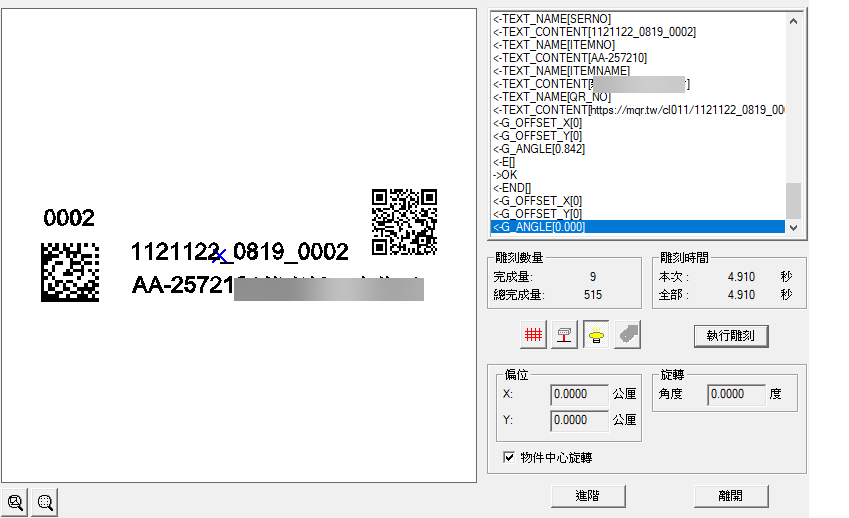

Engraving information and laser software links

After the template file is created, the engraving content and engraving position can be manipulated in the software.

Engraving information and laser software links

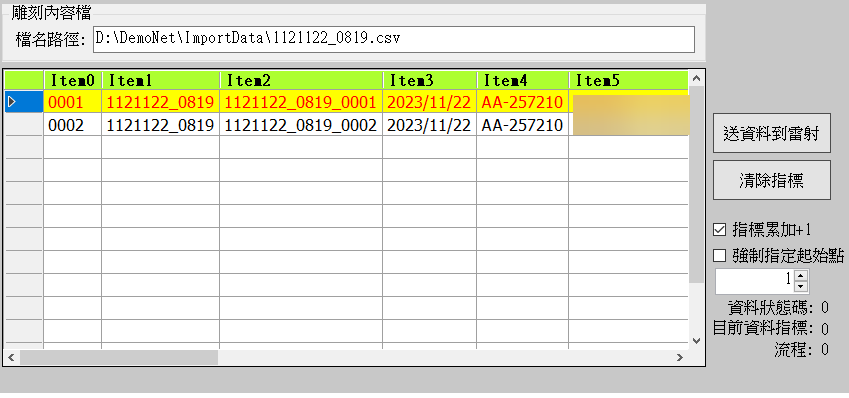

Engraving content information can be dynamically changed

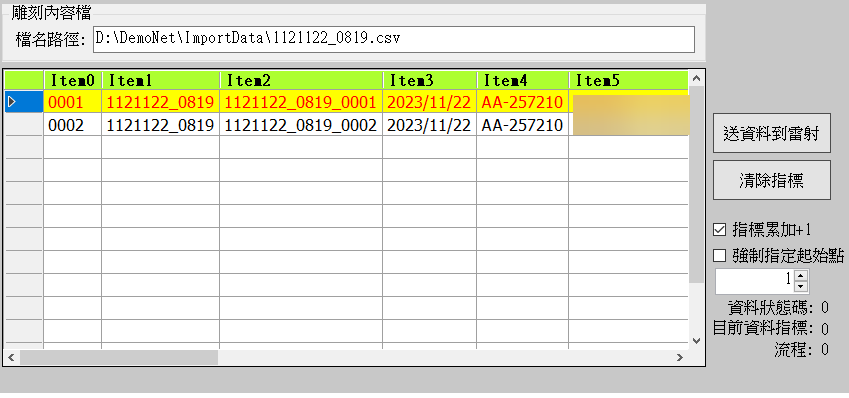

Engraving content information can be dynamically changed

Engraving content information can be dynamically changed

The engraving content can be dynamically changed based on work order information and filing information.

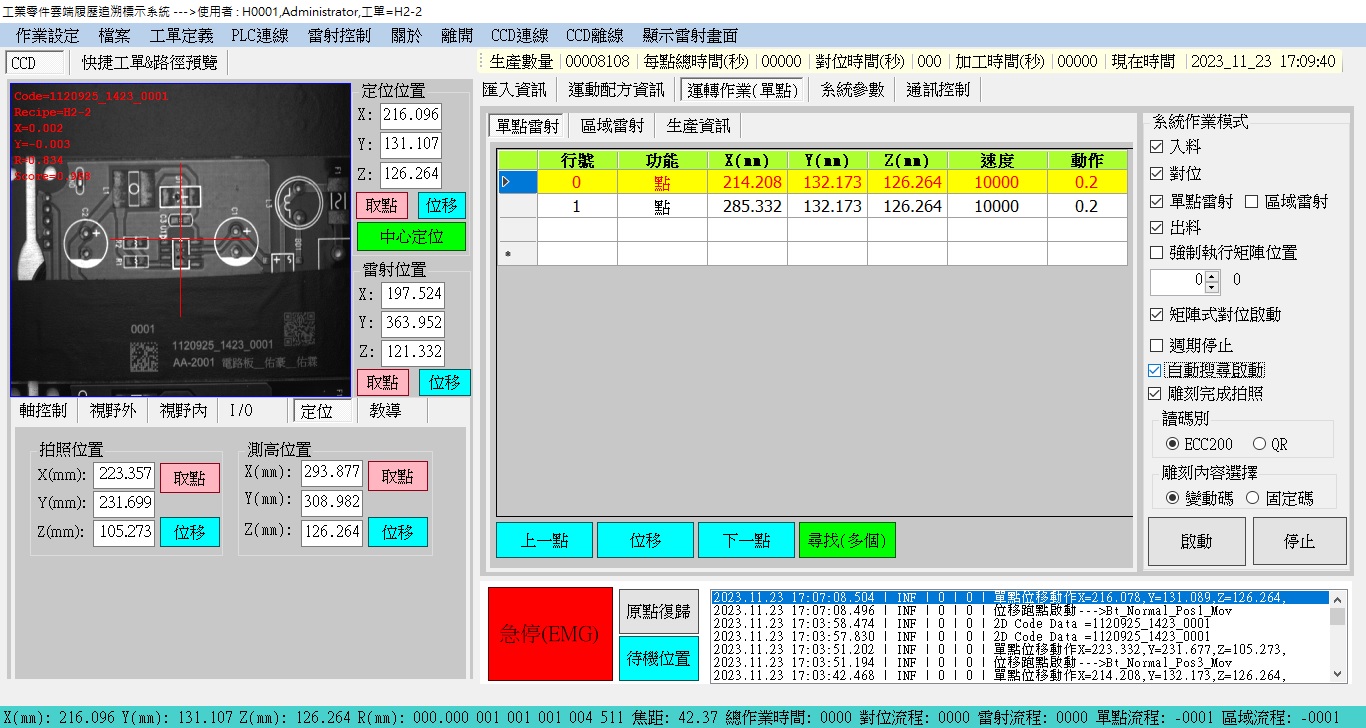

Object loop automatic search

When products are arranged in a matrix, tolerances can be set in the software to increase production efficiency.

Object loop automatic search

Automatic probe height measurement

Automatic probe height measurement

Through the automatic height measurement mechanism, you can save the need to adjust the laser focus due to the height of different products.

| Item | Value |

|---|---|

| Movement axis travel | X:700mm、Y:700mm、Z:100mm |

| Machine equipment size | 1000mm x 1000mm x 1900mm |

| Available Job scope | X:400mm、Y:400mm |

| Platform load | 20kg |

| Maximum operating speed | 500mm/sec |

| Repeatability accuracy | ±0.01mm |

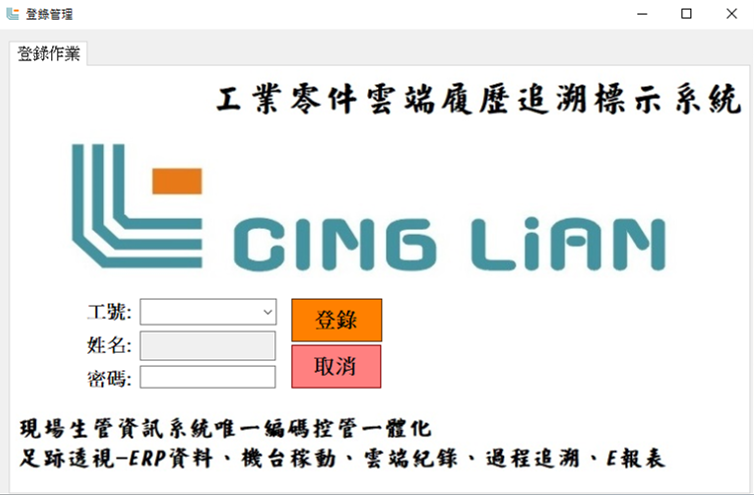

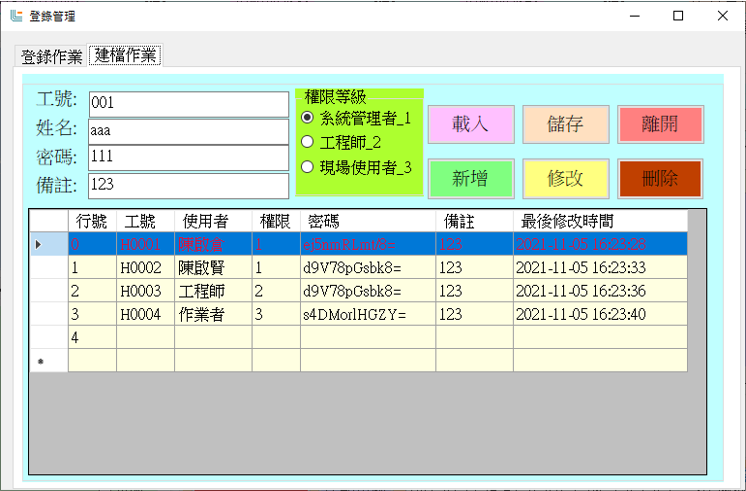

Personnel login permission control

Personnel login permission control

- Personnel login permission control

- Distance measurement outside field of view

- Distance measurement within field of view

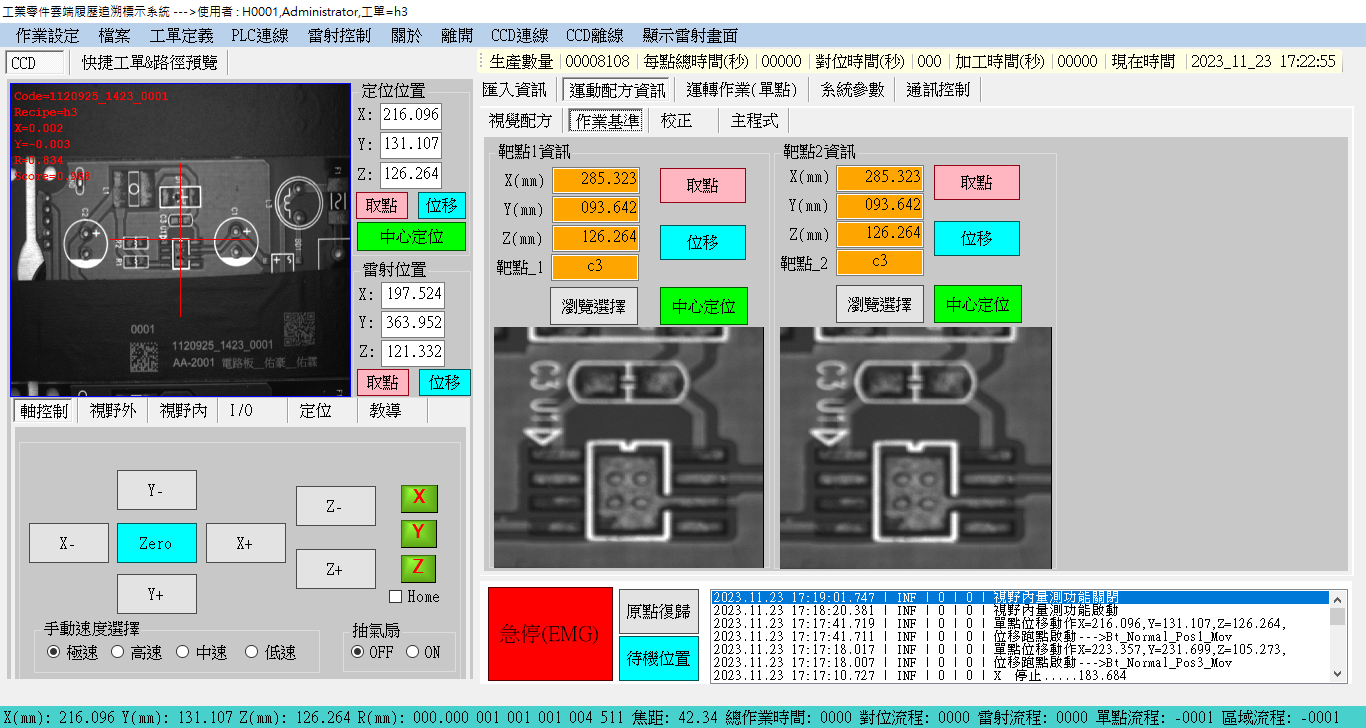

Distance measurement outside field of view

Distance measurement within field of view

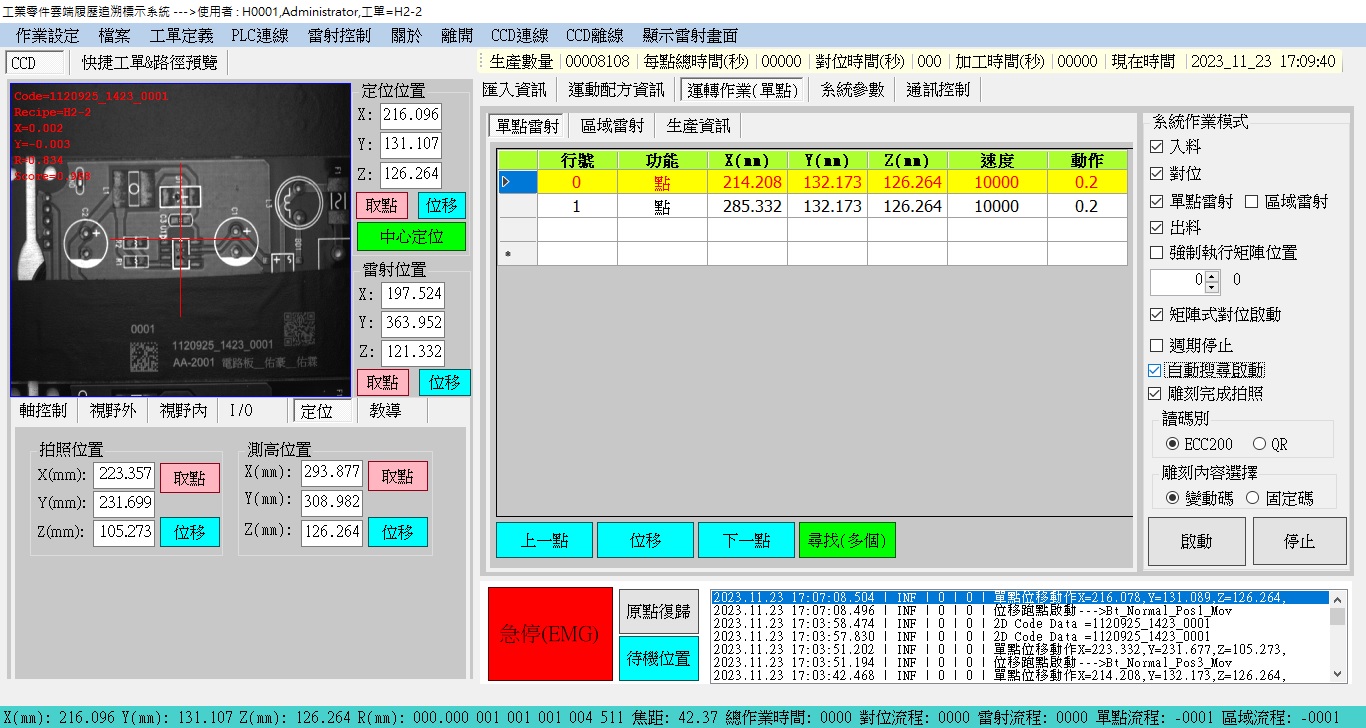

Point-to-point empty running alignment mode and production mode connection

Alignment information, work order link and template display

- Engraving point archiving

- Quick engraving point array and template copy and file creation

- Engraving relative position correction

- Quick and intuitive work order opening and preview

- Manual operation interface for each axis

- Process carving points

- Point empty running mode and production mode

- Calculable production quantity

- Running points at each single point position

- Engraving content can specify a specific starting point

- Single point mode and matrix process running point mode

- Engraving sample picture reference file and work order link

- Engraving information can be imported from external sources

- Engraving template file and work order link

- Engraving corresponding associated files

- The starting point of the engraving content data can be specified

- Engraving content can be changed dynamically

- Engraving content can be fixed

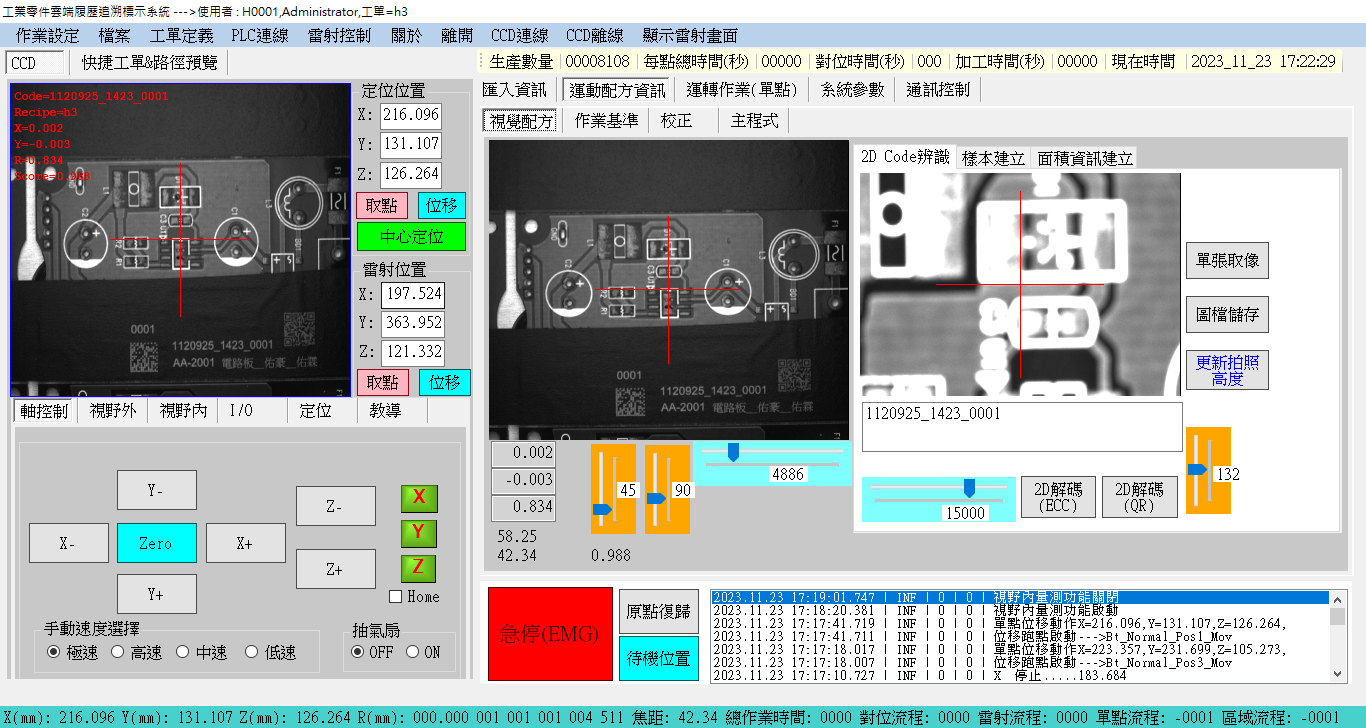

Engraving information and laser software links

Engraving content information can be dynamically changed

Engraving content information can be dynamically changed

Light source brightness adjustment

Object loop automatic search

Compare template files and recipe links

- Compare template files and recipe links

- Light source brightness adjustment

- Alignment data record

- Alignment image archiving

- Alignment information, work order link and template display

- Image recognition judgement center and error compensation

- Point-to-point empty running alignment mode and production mode connection

- Object loop automatic search

- Image judgment abnormality forced setting of output mode

| Item | Optional |

|---|---|

| Probe height measurement | O |

| Single glue gun dispensing glue | O |

| Double glue gun dispensing glue | O |

| ERP data transfer and import | O |

| Text file data conversion and import | included |

| Database data conversion and import | O |

| Order information printing | included |

| Barcode control scanning execution function | O |

| Barcode scanner order scanning and opening | O |

| Mobile device link | included |

| Line notification from machine | included |

| RFID machine usage management | O |

| Label printing | O |

| Connect to the Internet to upload record information (photography, engraving content, operation time) | O |

If the equipment specifications are different from your needs contact us for more information